Quality Overview

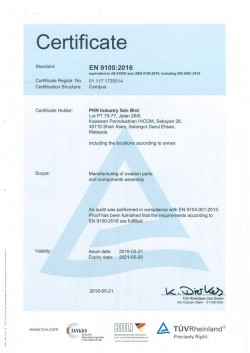

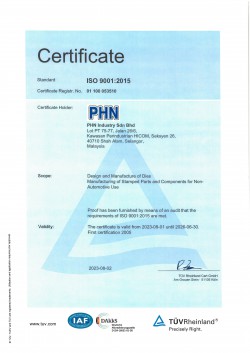

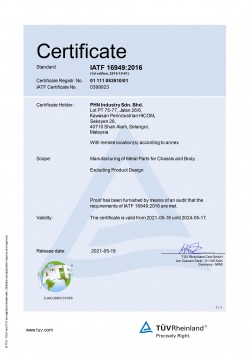

Achieving accreditation from the TUV Rheinland Group is no mean feat, and PHN achieved such an accolade by its unrelenting commitment to international industry standards and highest quality assurance. Its dedication to quality and best practices makes it an industry benchmark for production quality and declaration of its promise towards great work.

Its line operations, sub-assembled parts to dye manufacturing and process controls are all infused with high quality assurance practices, ensuring its customers get only the best automotive parts from PHN. Every production stage requires stringent inspections, and issues like raw material allocations, initial stage control to mass production, key line operations, audits, calibration exercises of precision tools and instruments all contribute towards making only the most reliable components with a zero-tolerance towards compromises in quality and benchmarks.

The Integrated Management System (IMS), which is an analytical best-of-breed framework, is a combination of ISO9001:2008 QMS, ISO/TS16949:2009 QMS, ISO14001:2004 EMS and OHSAS18001:2007 that helps analyse, monitor, document, measure and offer improvement-based planning strategies for production efficiency and optimisation of resources and productivity.

QUALITY POLICY

PHN strives to satisfy customer requirements through an effective and efficient production process utilising quality materials whilst ensuring total quality by forming a dynamic system, safe working environment and continuous training.

CERTIFICATION

Gaining quality assurance standards from benchmark authorities such as SIRIM QAS and TUV Rheinland Group is a testament to our attainment of industry best practices and quality assurances in our efforts to achieve global recognition for our products, namely for our quality. Other best practices certifications include: